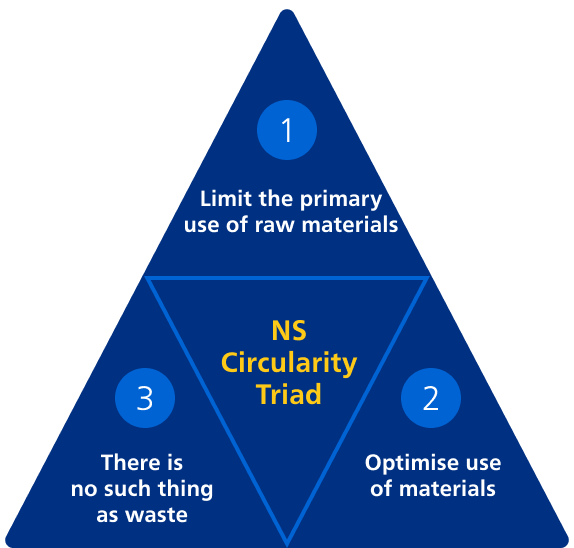

Circular enterprise

NS aspires to achieve full circularity in 2030 in terms of procurement, maximum reuse of materials and zero waste in offices and workshops and from trains.

Limiting the use of primary raw materials

Applying circularity principles in design and procurement will enable us to become even smarter in the use of materials and in reducing the use of primary raw materials. In relevant tendering procedures for materials, we include circularity as a criterion in the selection and award phase. This year, NS has taken steps to improve its insight into the circularity of all materials that enter the organisation. We use the CTI measurement method for this purpose, which was developed by the World Business Council of Sustainable Development (WBCSD). In collaboration with suppliers, we collect information about incoming materials to measure their circularity and favour circular purchasing based on used, recycled or easily renewable raw materials. In 2021, NS measured 49,000 tonnes (66%) of incoming materials. Of this amount, 91% was found to be circular. This percentage can be largely attributed to the construction of the shunting yard in Arnhem, a project that involved large-scale use of circular materials, such as used sleepers and ballast. In 2022, we will scale up the circularity measurements of purchased materials and integrate them into our standard purchasing processes.

Optimum use of materials

We take good care of our materials by focusing on effective maintenance and timely repairs so as to extend their service life. After twenty years of service, our double-decker trains are upgraded so that they can serve another twenty years. In 2021, the follow-up for VIRM1 trains has begun with the upgrading of 44 double-decker trains of the VIRM2/3 model. In this project we upgrade 85% of 20-year-old train components and reintegrate them in our trains for another twenty years of service. Of all materials, we put 13% to new uses elsewhere. In total, 99% of each VIRM2/3 train is given a new lease of life. For this project, Circular Train Modernisation, NS received the 2021 Circular Award.

That same year saw the exit of 157 carriages and 292 bogies of the 45-year-old SGM Sprinter trains. Before a train is decommissioned, mechanics remove all valuable components that can be used in operational SGM trains or for reuse in other series. For example, following a minor modification the wheel sets can be fitted under our ICM trains. We also dismantled 800 train windows from the SGM series and used them to build a bicycle parking facility near Eindhoven station.

There is no such thing as waste

If we have no further use for products and cannot reuse them, we still want to keep them in the cycle as high-value materials. We first try to find a new destination for the product as a whole. If that proves impossible, we find a new destination for separate components. If materials cannot be reused, we separate them for recycling purposes as effectively as possible. For example, in 2021 we sold 28 DM90 carriages and 2 SGM carriages. This enabled us to prevent 1,436 tonnes of waste and to give 30 carriages a new lease of life. In addition, we use old train components to make new products. For example, 45-year-old public announcement speakers from our trains are turned into bluetooth living-room speakers. Old floorboards, seats and ceiling panels from our trains are converted into items of furniture. In 2021, we opened an Upcycle Pop Up store at Utrecht CS for the fifth time, where we sell new products made from old NS materials. We also opened the first Upcycle Pop Up store at Leiden station. This enabled us to demonstrate, with our Upcycle partners, that there is no such thing as waste, that materials are valuable and deserve to be reused.

In addition, we found new destinations for old or redundant NS materials by auctioning them, and sold others via DB-Resale work platforms. In total, we repurposed 25 tonnes of materials for high-grade uses.

Outflow results

Promoting the sharing and worldwide upscaling of knowledge

We have learnt lessons from the circular modernisation and dismantling of our trains and translated these lessons into specifications for the acquisition of new trains. We are now scaling up these specifications at the European level. In addition, this year NS took on the role of co-chair of the UIC ‘Circular Economy’ Sector Group so as to promote a circular railway sector worldwide by 2035 in a joint effort with carriers and infrastructure managers.

Zero-waste stations by 2040

In recent years, we have gained a great deal of experience with reducing and separating waste at our stations. The Green Deal waste reduction and recycling targets proved to be unrealistic for the public spaces at our railway stations. Due to the many different types of packaging and other waste and the absence of standardised waste collection procedures in public spaces, a lot of waste ends up in the wrong bins and cannot be recycled for that reason. This is why we have decided to opt for simple and recognisable waste flows, for a focus on stations where the greatest impact can be achieved and for post-separation of residual waste. This approach enabled us to achieve a waste separation rate of 36% at our stations and in our trains in 2021: a threefold increase since the Green Deal was launched. We use the insights gained to help us realise our ambition, together with ProRail and the Ministry of Infrastructure and Water Management: zero-waste stations by 2040. We focus on preventing waste, making packaging materials more sustainable, collecting returnable packaging materials and optimising and further developing our waste separation policy. As one of the first organisations in the public space, NS is going to install collection machines for returnable PET bottles at several large stations. A tendering procedure for such machines was launched in 2021 and will result in the award of a contract and the supply of the first collection machines in 2022.